The biggest concern in manufacturing is "bonding technology". Currently used adhesives are one of the most popular "27 types" in Japan. Those to be bonded include MDF, particle board, LVL, sheet, glass, resin, metal etc. For example, you can bond different materials, which is usually said to be impossible, or bond with strength several times higher than general. We select the optimum adhesive and bonding method using test equipment in our company according to the nature and use of the base material.

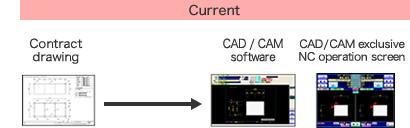

We will not compromise on quality and speed in manufacturing. As a result, with regard to factory facilities, it is not enough for ordinary general-purpose machines, and all the facilities that we introduced in the last few years are built together with equipment manufacturers.

![]()

![]()

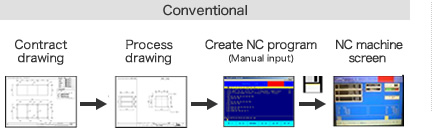

It is a production line that can correspond to both small lot and large lot. This equipment also supports CAD / CAM, Automatic calculation of work area from CAD data and optimum condition was figured out. This dramatically improved production efficiency, and in terms of quality, the incompatibility rate at flash became zero. In addition to this, we have created PUR adhesive lines and dowel driving machines.